Maximizing Operational Efficiency with the PMDC TF095CH Motor

In today’s fast-paced industrial world, achieving maximum operational efficiency is crucial for businesses aiming to stay competitive. One of the best ways to do this is by utilizing high-performance equipment, especially motors that drive machinery and processes. Among the various motor options, the PMDC TF095CH motor stands out as a powerful and efficient solution. This article delves into how the PMDC motor can help businesses maximize operational efficiency across various industries.

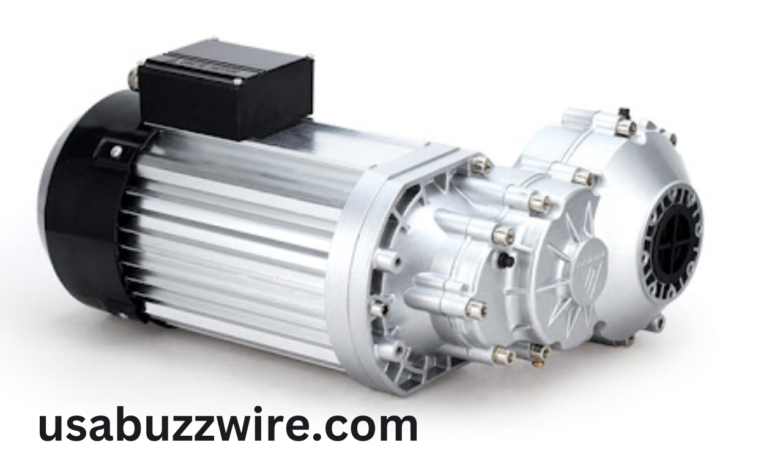

Introduction to the PMDC TF095CH Motor

The PMDC motor is a type of Permanent Magnet Direct Current (PMDC) motor. PMDC motors are known for their high performance, compact design, and efficient operation. The TF095CH model, in particular, offers reliability and precision, making it suitable for demanding applications. Unlike traditional motors that use electromagnetic coils to generate the magnetic field, PMDC motors use permanent magnets, which results in reduced friction and improved energy efficiency.

Key Features of the PMDC TF095CH Motor

Before exploring how the PMDC motor contributes to operational efficiency, it’s essential to understand its key features:

- High Efficiency: The motor’s design minimizes energy wastage, providing more power with less energy consumption.

- Compact Size: It offers a small footprint, making it ideal for applications with limited space.

- Low Maintenance: With fewer moving parts, the motor requires less frequent maintenance, reducing downtime.

- Precision Control: It delivers accurate control over speed and torque, essential for tasks requiring precision.

- Durability: Built with high-quality materials, the motor ensures long-lasting performance.

These features make the PMDC TF095CH motor an excellent choice for various industries, from manufacturing to medical equipment.

How the PMDC TF095CH Motor Enhances Operational Efficiency

1. Reducing Energy Consumption

One of the most significant advantages of the PMDC motor is its energy efficiency. Traditional motors often lose energy through friction, heat, and electromagnetic losses. The PMDC motor, however, minimizes these losses by using permanent magnets to create the magnetic field. This results in a more efficient conversion of electrical energy into mechanical energy.

By using less electricity for the same output, businesses can lower their operational costs. This is especially crucial for industries that rely on motors running continuously, such as manufacturing plants and conveyor systems. The PMDC motor can contribute to long-term energy savings, helping companies reduce their overall energy bills.

2. Minimizing Downtime and Maintenance Costs

Downtime can significantly impact a business’s productivity and profitability. The PMDC motor helps minimize downtime by being more reliable and requiring less maintenance. Traditional motors often experience wear and tear on brushes and commutators, leading to frequent repairs and replacements. In contrast, the PMDC TF095CH motor has fewer moving parts and doesn’t rely on brushes, reducing the risk of breakdowns.

This reliability ensures that businesses experience less downtime, allowing production lines and other systems to run smoothly without unexpected interruptions. The reduced need for repairs also lowers maintenance costs, freeing up resources that can be invested elsewhere.

3. Enhancing Precision in Critical Applications

Precision is a critical factor in many industries, especially those that rely on automation or robotics. The PMDC motor is designed to provide precise control over speed and torque, making it ideal for applications that require accuracy. For instance, in automated manufacturing systems or robotics, the motor ensures smooth, controlled movements, reducing the risk of errors and material waste.

By providing consistent and accurate performance, the PMDC motor helps increase the overall efficiency of production processes. This precision also contributes to the quality of the end products, reducing defects and the need for rework, which in turn saves both time and resources.

4. Compact Design for Space Efficiency

Space constraints are a common challenge in many industries. The PMDC motor addresses this issue with its compact size. Its small form factor allows it to fit into tight spaces where traditional motors might not be suitable. This feature is particularly beneficial in industries like electronics, medical devices, and automotive manufacturing, where equipment must be compact without compromising on performance.

The ability to integrate the PMDC TF095CH motor into space-constrained environments allows businesses to design more efficient systems and optimize the use of available space. In many cases, this can also lead to cost savings, as smaller systems may require less infrastructure and materials.

5. Long Lifespan and Durability

Another key factor in maximizing operational efficiency is ensuring that equipment lasts for a long time with minimal maintenance. The PMDC motor is designed for durability, offering a long lifespan that helps businesses reduce the frequency of motor replacements. This extended operational life not only lowers the cost of ownership but also reduces the frequency of downtime due to motor failure.

Because the PMDC motor is built to withstand harsh operating conditions, it is an excellent choice for industries that require robust, reliable equipment. This durability ensures that the motor continues to operate efficiently for many years, providing a consistent performance that contributes to overall operational success.

Applications of the PMDC TF095CH Motor

The versatility of the PMDC motor makes it suitable for a wide range of applications. Some of the key areas where this motor is particularly effective include:

Automation Systems

In automated manufacturing systems, the PMDC TF095CH motor is used to power robotic arms, conveyors, and other automated equipment. Its ability to deliver precise control over speed and torque makes it an ideal choice for tasks that require accuracy, such as assembly, sorting, or packaging.

Consumer Electronics

The PMDC motor is also used in consumer electronics, such as electric toothbrushes, fans, and small appliances. Its compact size and energy efficiency make it an attractive option for portable devices that require reliable and efficient motors.

Medical Equipment

In the medical field, the PMDC motor powers a range of devices, from imaging machines to diagnostic tools. The motor’s precision and low maintenance make it ideal for medical applications where reliability and accuracy are paramount.

Aerospace and Defense

The PMDC motor is used in aerospace and defense applications, where high performance, precision, and durability are crucial. Its ability to operate in demanding conditions makes it suitable for use in aircraft systems, satellite technology, and other high-stakes applications.

Maximizing the Benefits of the PMDC TF095CH Motor

To fully harness the operational efficiency of the PMDC TF095CH motor, businesses should ensure proper integration and maintenance. Proper motor sizing and installation are critical to achieving optimal performance. Overloading or misapplying the motor can lead to inefficiencies and increased wear.

Regular maintenance is also important, although the PMDC motor requires less upkeep than traditional motors. Periodic inspections and checks can help identify potential issues before they lead to downtime or system failures.

Conclusion

The PMDC motor is a highly efficient, reliable, and versatile motor that can significantly enhance operational efficiency in a wide range of industries. Its energy efficiency, low maintenance, precision control, and compact design make it an ideal choice for businesses looking to improve performance, reduce costs, and minimize downtime. By incorporating the PMDC TF095CH motor into their operations, businesses can optimize their systems and enjoy long-term cost savings, ultimately driving productivity and success.

Alyson H Belcourt Email Address Connecting with a Leading Expert