Key Features to Look for in CNC Turning Service Suppliers

It is necessary to select the most suitable CNC turning service supplier to meet all the quality standards and precision that the manufacturers are trying to achieve while operating at optimal costs. As more companies push for high precision in their preferred machining services, procuring services from an authentic precision machining supplier guarantees the completion of your projects to your exact specifications. The present article discusses the criteria to be used while identifying suitable CNC turning suppliers and how these parameters influence the effectiveness of your manufacturing operations.

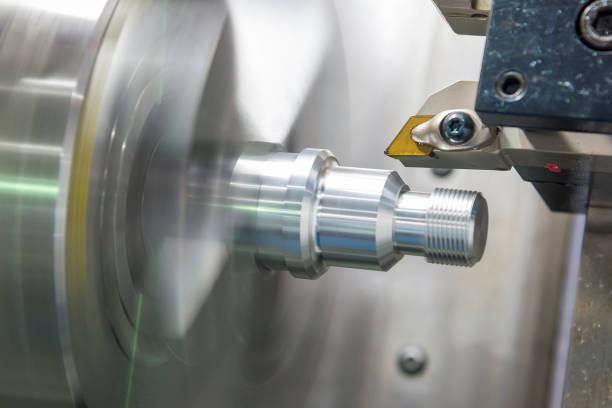

Advanced Technology and Equipment

Perhaps the most important requirement for a world class CNC turning service provider is the ability to offer the latest technologies and machinery. Examples of advanced computer controlled production technologies which can be leveraged by suppliers include multi axis turning centers that can handle demanding geometries, strict tolerances, and massive production demands. Thanks to today’s advanced CNC technology, one is guaranteed of high accuracy and consistency thus making products with precise parts more possible. These include aerospace, automobile, and medical device industries where even the slight deviations can be destructive.

In addition, it cuts production times and material wastage since new technologies enhance product 많이 advanced equipment also minimizes production times and amounts of wastage since improved procedures and cutting trajectories are facilitated. This makes suppliers and their clients save a lot of money because of the minimized costs of the supplies. An automotive aluminum precision machining supplier exercising capital procurement for modern technology equipment proves compliance with the changing market forces to provide quality services. Additionally, such tools create an opportunity for suppliers to undertake tasks of diverse developments, which significantly enhances their capacity to deliver both basic and complex machining functions.

Quality Assurance and Certifications

When selecting a CNC turning service supplier, the services need to be quality assured throughout the whole manufacturing cycle. This includes inspections, tests and documentation that goes with the product as well as other measures put into check to ensure that all parts and components used conform to requirements of the industry and or the client’s demands. Quality assurance decreases the number of mistakes, reduces the need for repeat work and consequently is time and cost efficient while maintaining quality of the output.

Certifications such as ISO 9001:This is the AS9100 for aerospace industry or IATF 16949 for automotive industry as a testimony to a supplier’s commitment to quality. These certifications are not a luxury for industries which have specific needs; they are a necessity. When a company collaborates with a certified supplier of precision machining services, then they can be assured that their products are of standard quality as produced with a lot of concern. Also, a computerized optical inspection, or even a CMM device can also help in improving the quality of inspection. They independently check and verify each detail of the component and provide confidence to the clients.

Customization and Flexibility

It is always the case that every manufacturing project is defined by its requirements and that is why it is so important when choosing a CNC turning service supplier, customization and flexibility must be on the list of priorities. The versatility of a supplier who can accommodate certain project requirements in terms of prototyping, advanced designs or simply volume requirements is a definite asset. Customization includes working with special materials, different dimensions, or complex design, while flexibility means that the supplier has to change timings or have conditions to fulfil additional requests at the last moment.

Flexibility also translates to supplying high services to both small and big quantities of orders as a CNC turning supplier. In the subject of supply chain management, a supplier that possesses the ability to extend its capacity to produce according to the capacity of its clients is more ready to face fluctuating market environments. Moreover, it is very beneficial to have a supplier who can pick up the phone and guide during the design phase as to which material can be used, or the design of components can be improved to ensure they are easier to manufacture. From the perspective of clients, it is always important to work with a precision machining supplier that values customization and flexibility that guarantees every client full satisfaction regarding his/her needs that may sometimes be hard and almost impossible to meet as they are very specific.

Communication and Customer Support

One key success factor that relates to a dependable CNC turning service supplier lies in communication. At every stage of product manufacture, from the preliminary discussion to the issuance of the final product, the door is opened for honest communication to avoid the计划 of misunderstandings arising and getting out of hand. Companies that supply customer support services are apt to provide businessmen with timely information, solutions to technical problems, and manage their expectations enhancing the efficiency of the business relationship.

In the case of a precision machining supplier, effective communication is the extent that a company is willing to discuss project requirements and executing objectives, propose worthwhile design adjustments, and present status changes in work. That a supplier employs open communication also creates a channel of trust with the client, helpful in long term projects. When conducting evaluation of CNC turning suppliers, potential suppliers should be observant of how they treat those inquiries at the evaluation stage. Professional and informed communication allows a supplier to demonstrate that it values the client’s business and will attend to the client with professionalism and professionalism. Large or change projects require particularly good communication with other people for it can lead to serious consequences in the form of delays or misunderstandings.

Conclusion

It is therefore important for one to select the right CNC turning service supplier in today’s fast growing manufacturing industry. When sorting out the best providers ofлуг relief services one should look out for the following features: advanced technology and equipment, strict quality assurance procedures, the ability to offer customized services and good communication. From these attributes, one can be appreciated as a good way for businesses to compare CNC turning suppliers to the needs of a project before choosing them for the job due to the superior results.

Finding a quality precision machining partner centrally located to your manufacturing processes guarantees you value, quality, and profitability. No matter if it is small and detailed components’ prototypes or big parts – the choice of the supplier can define success on the production. In this case, do not rush into choosing a partner; instead, take your time and assess your choices for a competent partner for a company that values quality, measurement accuracy and customers’ satisfaction. Working with such a supplier means that your business will be on the right side of the efficient and reliable market producing high quality outcomes.